There are also some jobs where safety considerations are minimal, but quality control required the correct identi-fication of colours (e.g. in industries such as textiles, paper manufacture, dyes and paints.

If an employer has employees whose colour vision is important for safety critical purposes then colour vision testing is crucial in deciding on their fitness for work. When colour vision needs are associated with product quality then colour vision testing is valuable to avoid costly error

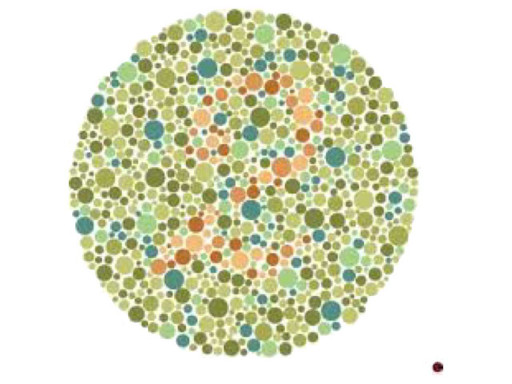

Colour vision defects

A person with a colour vision defect perceives a wide range of different colours as being the same, which to a colour normal person appear to be different. The colour confusions are variable and can be mild, moderate or severe (colour blindness—a total lack of colour vision). Approximately 1 in 12 men and 1 in 200 women suffer from some form of defective colour vision. Defective colour vision is usually inherited (from mother to son, usually red/green), although it can be acquired as a result of eye disease or as a side effect of medication or toxic poisoning. There are three classes of colour deficiency: red (protanopia), green (deutanopia) and blue (tritanopia confusion between blue and yellow, violet and red, and blue and green). A colour vision deficiency is unlikely to constitute a disability for the purposes of the Disability Discrimination Act 2005.

Assessments and testing

If colour vision assessment is required in order to evaluate the ability to perform one or more specific tasks this is often carried out at the pre-employment stage. In addition, annual checks for possible acquired defects are desirable in certain work situations. Tests are used to ensure that the worker can perform all tasks efficiently and safely, and also for those over 40 years of age. The policy for colour vision testing should be implemented throughout the company, ensuring that all staff have been consulted/notified, the level of colour vision considered acceptable for a given work task has been defined, the examiners are competent, appropriate testing conditions are used and procedures are in place for recording results, maintaining records and informing management of the results.

Colour coding

Colour codes are important in the workplace as a means of establishing, by visual clues, specific information that a worker needs to perform a task either safely or more efficiently. There are two types used regularly connotative (colour is the only means of information transfer and the code has to be identified correctly to ensure the safe operation of the activity) and denotative (enhances information that is provided by other distinguishing features such as position, sequence, shape or text)

Should you require further advice please contact us on 01722 326 390.